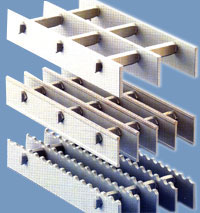

Aluminum Swaged & Press-Locked Bar Grating

Swaged Bar Grating is mechanically locked with cross bars to the bearing bars, All nodal points between bearing bars and cross bars are welded by forming a construction to offer a high load bearing capacity. offer swaged bar grating in aluminum and stainless steel and can custom manufacture swaged bar grating in carbon steel on request.

Aluminum grating is corrosion-resistant, non-sparking, and rustproof. It has many applications due to its light weight and high strength. It is ideally suited for use in corrosive environments and finds wide applications as walkways and platforms in sewage treatment plants, refineries, chemical processing plants, pumping and compressor stations, and aboard ships and barges. Because it does not rust, it is commonly used in breweries, bottling plants, and food preparation and storage facilities. In munitions plants and other volatile industries and areas, its non-sparking properties make it a must for safety. It is available in standard or anodized finishes.

Copyright © 2023 Metallic Forge. All Rights Reserved.